Industrial wastewater is defined as the polluted water created as by-products of commercial and industrial activities which often contain harmful chemicals and other pollutants. This waste water used to be released in to the environment which caused severe detriment to the ecology and even humans living in the area in the past. Today this practise is highly regulated and industrial wastewater needs to be treated in specific ways, based on the actual composition of the wastewater, before being allowed to enter a public sewage system or to be pumped out on the surface. Some of the pollutants that are found in industrial wastewater include cyanide, sulfates, chromium, oil, acids, metals, salts, phenols, chlorine, organic compounds, fluorine, solvents and other chemically oxidized particles.

There are a number of ways that are used to treat industrial wastewater before it can be safely released in to the environment. These include:

Brine treatment: This process removes excess salt while taking in to account the metal and other hardness ions in the water. Specific processes will be used in each type of processing plant to ensure the water is treated correctly for the pollutants present.

Removal of grease and oils: There are a number of processes used to remove oil in a variety of states. Dissolved oil is the hardest to remove and is often only detected by testing equipment. Emulsified oil is a little easier to remove, but still a lot more complicated than heavy oil which sinks to the bottom and is often attached to other pollutants. Free oil refers to large drops of oil floating on the surface of the waste water, which are easiest to detect. This type of pollutant is often removed via a separation process, which will differ for each oil density.

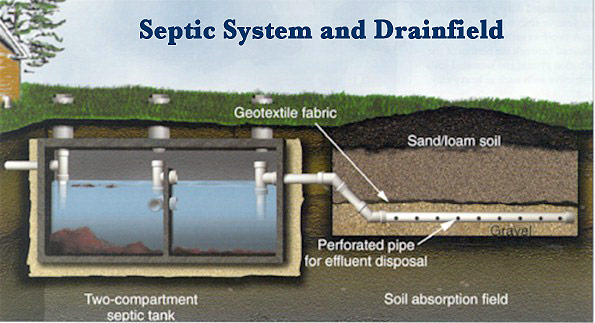

Removal of solids: Processes such as flocculation, filtration or ultrafiltration may be used to removal particles or larger solid material from the wastewater. Many solids are removed via a sedimentation process which recovers a sludge or slurry which is then processed further. Removal of these solids is a lot more expensive than a new septic tank cost. The solids in these processes are not the same as in the usual sewage industry.

Biodegradable organics removal: These organic materials are more likely to be treated along the same lines as conventional sewage. You may need to factor in a new septic tank cost if you were looking to try and remove this type of pollution the old fashioned way. The level of dilution with other harmful pollutants can cause an issue here as water that contains pesticides, hard cleaning chemicals, disinfectants or antibiotics cannot be treated conventionally. Also natural biodegradable organic material that is undiluted such as milk or blood would need to be treated in a different manner to normal. The usual method includes an activated sludge process, an aerated and a settling tank. There is also a trickling filter process to remove many solids. Other treatments will be very specific to remove harmful chemicals, acids, alkalis and other toxic materials before release in to a sewage system. For a smaller company with minimal biodegradable organic material, a new septic tank cost might be looked at to store the material before treatment.

It is important that all manufacturing or treatment plants that produce industrial wastewater ensure that they have the most effective treatment systems for their specific pollutants to ensure the water released in to the sewers and environment will not have a long lasting detrimental effect on the systems or the environment.