What is 3D Printing?

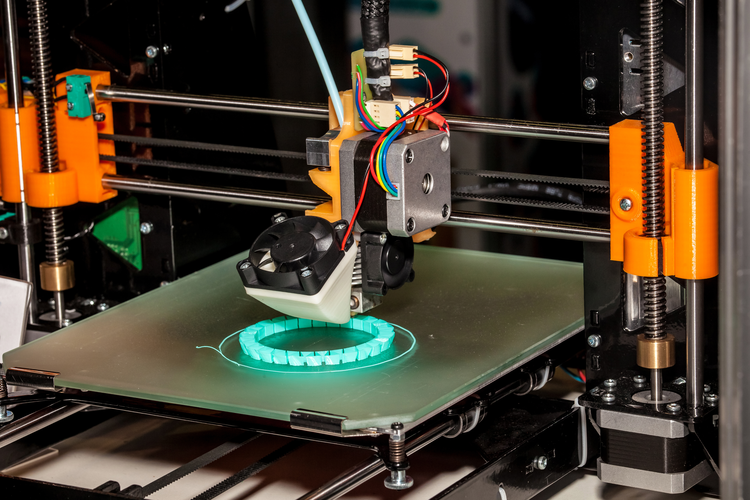

3D Printing is also known as Additive Manufacturing. This process involves the making of three-dimensional objects directly from CAD, which is design mainly computer-aided. There are some of the additive processes that contribute to the making of these solid objects. With 3d printing, it is possible to produce certain objects with a complex shape. It involves the use of fewer materials as compared to the traditional methods of manufacturing. In this additive process of manufacturing, many materials are added in successive layers that are sliced very thinly as the original object’s horizontal cross-sectioning.

Benefits of 3D Printing

The technology of 3d printing is progressing with time. This has been possible because of the various benefits that are offered by 3d printing.

- Each part can be customized: Unlike in traditional manufacturing, it is comparatively easier to customize each part in 3D printing. The only thing that needs customization in 3D printing is the digital model. 3D printing can be customized as per the needs of the user, without affecting the initial cost price.

- Low initial cost: In 3D printing, it is, in fact, an advantage that no unique molding or any special tools required during the manufacturing process. So, there is as such no need for any extra expenditure required. So, the initial cost of 3D printing is quite low. The expenditure, however, is completely dependent on the materials being used, in the time taken by the machine to carry out the printing process, and finally in the processing of the finished product.

- Complexity in molding at no cost: With 3D printing, fabrication if any desired complex shape can be done. This process does not charge any extra cost, no matter how complex the parts are in 3d printing.

- Cost-Efficient Prototyping: 3D printing allows the prototyping for both function and form. In this case, as well does not require any extra cost and is managed well with the overall costing of the printing procedure.

- Easy Delivery: The parts of 3D printing apart from being cost-efficient are also prepared and delivered either overnight or take at most 5 weeks. The prototyping speed accelerates the designing process quite fast.

3D Printing: Applications

3D printing can prove to be useful in a number of fields. The application of 3D printing can be seen in

- Maritime Industry

- Healthcare and Medical

- Architecture and Construction

- Mechanics

- Chemical Industry

- Food Industry

- Aeronautics and Aerospace

- Automotive

- Fashion and Textile

- Broadcasting and Entertainment

- Optics

- Electronics

- Education

- Energy

Types Of 3D Printing

3D Printing is of different types that had been categorized separately. Some of these types available are-

- FDM or Fused Deposition Modelling

- SLA or Stereolithography

- SLS or Selective Laser Sintering

- DLP or Digital Light Processing

- MJ or Material Jetting

- MBJ or Metal Binder Jetting

- SBJ or Sand Binder Jetting

- DMLS or Direct Metal Laser Sintering

- SLM or Selective Laser Melting

- EBM or Electron Beam Melting

With these 3D printing technologies, manufacturing in all the fields has become much easier and cost-effective.