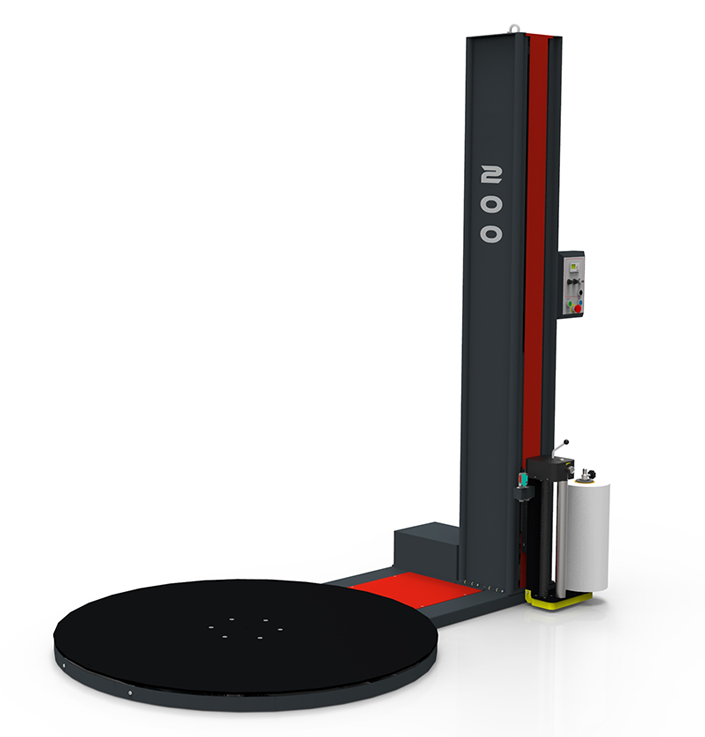

The Turntable stretch wrapping machine uses an electric platform to rotate the stretchable film roll. As the load rotates, the rollers roll up and down to apply a uniform film layer. The turntable system is ideal for small to medium-sized packaging solutions and can pack 20 to 40 pieces per hour.

Semi-Automatic Stretch Wrapper

The semi-automatic rotating turntables packaging system provides a simple disk and placement method for delivering the package. On the low turntable, you can use a forklift or pallet truck to load the load directly onto the turntable. The operator needs a semi-automatic turntable stretch wrapper to start the cycle and manually load and unload the workbench. The semi-automatic Turntable Stretch machine can pack 20 to 30 packages per hour.

The European-made pallet packing machine has a photocell that automatically detects pallet heights up to 2.4 meters by default. The base has front and rear slots that allow the truck to move the machine easily and securely into the work area. The articulated mast is patent and requires no external wiring or limit switch. Clear identification tags make it easy to use.

The physical requirements and inconsistencies of manual stretch wrapping are two of the reasons most Pallet Wrapping Machine Manufacturer today use stretch wrappers. These pallet wrappers provide the professional look that your customers need for your pallet shipments, while providing a sure way to unify freight in a consistent and safe manner.

Semi-automatic stretch wrappers require the operator to place a tray on the stretch wrap to start a stretch wrapping cycle. The stretch film sticks the stretch film and packs the tray loading capacity to meet the requirements. If the package requires 10 pallets per day, the pallet wrapping machine may be reasonable.

Companies manufacture these series of machines to high quality standards and improve building specifications. Because of the high level of satisfaction in the world, these machines have become the top priority of the end product, which has allowed it to use horizontal wrapping technology for stretch films.

Because of the wide range of ring diameters, this range of machines covers a wide range of packaging needs. Specialist stretch wrapper for wrapping windows and doors are distinguished by versatility and ease of use and combine them with the high quality levels of placement of these products in their category.

Functionality

The Spool carriage includes a direct transfer roller that is adjustable to facilitate the loading of the spool and the insertion of the film. They equip the spool stand with a reel lock and quick release. The double bar clamping and cutting system fully automates the packaging process.