Deep hole drilling is a widely used machining process aimed at creating precise holes with a high depth-to-diameter ratio. Whether in the fields of aerospace, automotive, or oil and gas industries, this intricate process plays a fundamental role in manufacturing complex components. What makes deep hole drilling so unique is its ability to combine accuracy, efficiency, and consistency. But how does it work, and what are the key principles behind it? This article breaks down the science behind this essential technique.

What Is Deep Hole Drilling?

Deep hole drilling involves creating holes that are at least ten times deeper than their diameter. Traditional drilling methods fall short under such conditions because they cannot provide precision or effectively remove the excess material, known as chips. Deep hole drilling bridges this gap by employing specific tools and techniques that make the process smoother and more accurate.

Key Characteristics of Deep Hole Drilling

- High Aspect Ratio: Deep hole drilling is defined by its focus on producing holes with a depth significantly greater than the diameter.

- Chip Removal: Special mechanisms like internal coolant systems ensure continuous removal of debris.

- Dimensional Precision: The process delivers exceptional straightness and surface finish, critical for high-performance components.

- Custom Tooling Solutions: Tools are often selected or designed based on the material, depth, and diameter required for the hole.

Understanding these foundational aspects is key to mastering the science of deep-hole drilling.

The Physics Behind the Process

The success of deep-hole drilling hinges on several scientific principles, including material mechanics, thermodynamics, and fluid dynamics. Each plays an essential role in the effectiveness of the operation.

Cutting Force and Tool Dynamics

The friction between the drill and the material generates cutting forces, which need to be controlled to avoid tool deflection. By designing drills with optimized geometries, manufacturers ensure precision even at great depths.

Controlled force distribution also minimizes vibration, reducing the likelihood of error in what is often a sensitive, high-stakes process.

Heat Management

Drilling deep into a material generates significant heat due to friction. This is problematic as excessive heat can damage tools and compromise the material’s structural integrity. Coolant systems are integrated directly into the drilling tools to dissipate heat, improving efficiency and prolonging the lifespan of the equipment.

Lubrication and Chip Evacuation

Lubricants and oils not only cool the drill but also help in evacuating the chips formed during the cutting process. Improper chip removal could lead to blockages, causing inaccuracies or tool breakdowns. By using high-pressure internal fluid systems and vacuum mechanisms, debris is continuously removed while maintaining high-quality results.

Techniques and Tools for Deep Hole Drilling

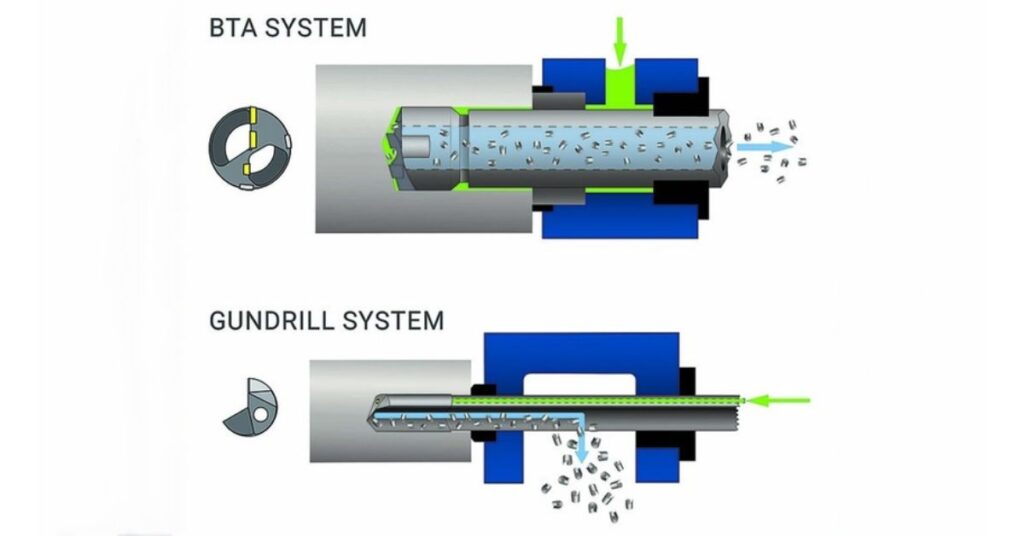

There are various techniques used to carry out deep-hole drilling, and the selection depends on the desired output and characteristics of the material.

Gun Drilling

Gun drilling is a method that involves small-diameter tools capable of creating deep, straight holes. Named for its original use in crafting firearm barrels, today it is widely applied in industries requiring precise holes.

- Uses: Aerospace and medical components.

- Advantages: Remarkable accuracy and finish.

- Limitations: Limited to smaller diameter holes.

Boring and Trepanning

Boring enlarges an existing hole, while trepanning involves cutting a circular groove to create a hollow part. Both are used for larger-scale projects or materials.

Other Drilling Techniques

- Coring: Efficient for large-scale projects needing a core removed.

- Single-Lip Drilling: Used when straightness is non-negotiable.

Each drilling method offers specific advantages and is selected based on project needs.

Applications in Various Industries

Deep hole drilling is critical in industries where precision and durability are key. Some notable applications include:

- Aerospace: Used to create cooling channels in jet engines and hydraulic components.

- Automotive: Plays a role in manufacturing engine blocks and crankshafts.

- Oil and Gas: Enables precise tooling for equipment like pipes and well components.

The use of advanced technologies, including robots and CNC machines, ensures that even the most challenging drilling tasks are completed with efficiency.

Challenges in Deep Hole Drilling

Despite its advantages, this process also comes with unique challenges:

- Material Hardness: Certain alloys require specialized tools and methods to drill effectively.

- Tool Maintenance: Wear and tear on tools increases with depth and material toughness.

- The complexity of Downhole Tool Conversion: Adapting tools to meet specific project requirements demands precise engineering and meticulous planning.

Technology, combined with skilled operators, has enabled the industry to tackle these hurdles, ensuring accuracy and efficiency.

The Growing Role of Innovation

Advancements in materials science and manufacturing technology are rapidly improving the scope and efficiency of deep-hole drilling. CNC machining, AI-based process monitoring, and hybrid drilling methods are shaping the future of this field. These innovative solutions allow businesses to meet increasingly complex demands while reducing costs and improving sustainability.

Conclusion

The science behind deep-hole drilling demonstrates how rigorous engineering and advanced technologies come together to solve some of the most challenging problems in manufacturing. By understanding the underlying principles, industries can unlock new possibilities and push boundaries in design and production.

Whether for aerospace innovation or energy solutions, deep-hole drilling remains at the core of modern engineering.

Also Read: Formula 43: The Ultimate Performance Cruiser in Its Class